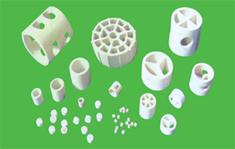

Ceramic tower packing

Ceramic packings have excellent acid resistance and heat resistance .Them can resist to corrosion of various inorganic acids,organic acids and organic solvents except hydrofluoric acid ,and can be used in high or low temperature conditions.consequently their application ranges are very wide.The packings can be used in the drying columns,absorbing columns,cooling towers,scrubbing towers in chemical industry,metallurgy industry,coal gas industry,oxygen producing industry,etc.

chemical composition

SiO2 |

Al2O3 |

Fe2O3 |

Cao |

K2O+Na2O |

>70% |

23-30% |

<1% |

1-2% |

2-4% |

|

|

|

Ceramic Rashing ring, (Raschig ring, Rasching ring)

|

Size |

DxHxT

mm |

Compare Area

m2/m3 |

Void

rate

% |

Bulk Number

n/m3 |

Bulk Density

Kg/m3 |

Dry gene

m-1 |

?6 |

6x6x2 |

489 |

0.73 |

3110000 |

650 |

2030 |

?10 |

10x10x2 |

360 |

0.7 |

720000 |

600 |

1280 |

?15 |

15x15x2 |

250 |

0.7 |

250000 |

550 |

960 |

?25 |

25x25x2.5 |

147 |

0.78 |

49000 |

500 |

310 |

?50 |

50X50X4.5 |

80 |

0.81 |

5600 |

460 |

156 |

|

Ceramic ladder ring

|

Size |

DxHxT

mm |

Compare Area

m2/m3 |

Void

rate

% |

Bulk Number

n/m3 |

Bulk Density

Kg/m3 |

Dry gene

m-1 |

?25 |

25x20x3 |

270 |

0.74 |

74000 |

600 |

172 |

?50 |

50x30x5 |

108.8 |

0.787 |

9100 |

550 |

223 |

?76 |

76x45x7 |

68.4 |

0.79 |

2517 |

500 |

126 |

|

Ceramic pall ring

|

Size |

DxHxT

mm |

Compare Area

m2/m3 |

Void

rate

% |

Bulk Number

n/m3 |

Bulk Density

Kg/m3 |

Dry gene

m-1 |

?25 |

25x25x3.0 |

238 |

0.73 |

49000 |

480 |

565 |

?38 |

38x38x4 |

197 |

0.75 |

13400 |

500 |

365 |

?50 |

50x50x5 |

120 |

0.78 |

6800 |

460 |

252 |

?80 |

80x80x8 |

75 |

0.8 |

1930 |

450 |

146 |

|

Ceramic saddle ring for RTO

|

Size |

DxHxT

mm |

Compare Area

m2/m3 |

Void

rate

% |

Bulk Number

n/m3 |

Bulk Density

Kg/m3 |

Dry gene

m-1 |

?25 |

25x20x3 |

216 |

0.78 |

76600 |

460 |

340 |

?38 |

50x30x4 |

157 |

0.84 |

24600 |

450 |

190 |

?50 |

50x42x6 |

88.4 |

0.81 |

8260 |

480 |

166 |

?76 |

76x53x9 |

58.4 |

0.77 |

2430 |

500 |

127 |

|

Ceramic conjugate ring

|

Size |

DxHxT

mm |

Compare Area

m2/m3 |

Void

rate

% |

Bulk Number

n/m3 |

Bulk Density

Kg/m3 |

Dry gene

m-1 |

?25 |

25x25x3 |

175 |

0.78 |

74000 |

550 |

350 |

?38 |

38x38x4 |

118 |

0.80 |

13950 |

510 |

230 |

?50 |

50x50x5 |

72 |

0.80 |

6806 |

490 |

140 |

|

Ceramic saddle ring

|

Size |

DxHxT

mm |

Compare Area

m2/m3 |

Void

rate

% |

Bulk Number

n/m3 |

Bulk Density

Kg/m3 |

Dry gene

m-1 |

?16 |

16x12x3 |

376 |

0.71 |

26990 |

530 |

1055 |

?25 |

25x20x2 |

200 |

0.77 |

58230 |

500 |

434 |

?38 |

38x30x4 |

138 |

0.80 |

19680 |

460 |

252 |

?50 |

50x40x6 |

115 |

0.79 |

8246 |

500 |

213 |

?76 |

76x53x9 |

86 |

0.75 |

2400 |

490 |

179.4 |

|

Ceramic Cross-partition ring

|

Size |

DxHxT

mm |

Compare Area

m2/m3 |

Void

rate

% |

Bulk Number

n/m3 |

Bulk Density

Kg/m3 |

Dry gene

m-1 |

F50 |

50×50×5 |

135 |

50 |

500 |

5600 |

1080 |

F80 |

80×80×8 |

120 |

53 |

750 |

2100-2500 |

806 |

F100 |

100×100×10 |

110 |

56 |

730 |

900-1000 |

626 |

F150 |

150×150×15 |

60 |

58 |

650 |

270-300 |

308 |

|

Ceramic connecting

|

Size |

DxHxT

mm |

Compare Area

m2/m3 |

Void

rate

% |

Bulk Number

n/m3 |

Bulk Density

Kg/m3 |

Dry gene

m-1 |

2A |

115X25X4 |

180 |

68 |

720 |

800 |

655 |

3A |

115X30X5 |

130 |

70 |

700 |

750 |

432 |

4A |

240X50X5 |

90 |

74 |

610 |

720 |

286 |

5A |

300X60X8 |

80 |

75 |

580 |

700 |

233 |

|

Catalog:

1. Inert Ceramic Ball as Catalyst Support Media(Equivalent to Donstone Series)

2. Ceramic Random Packing:

(1). Ceramic Pall Ring

(2). Ceramic Raschig Ring

(3). Ceramic Cross-Partition Ring

(4). Ceramic Intalox Saddle Ring

(5). Ceramic Supper Intalox Saddles

(6). Ceramic Cascade-mini Ring

3. Metal Random Packing:

(1). Metal Pall Ring

(2). Metal Raschig Ring

(3). Metal Intalox Ring(Equivalent to IMTP)

(4). Metal Nutter Ring

(5). Metal VSP Ring

(6). Metal Cascade-mini Ring

(7). Metal Conjugate Ring

P. S. Metal availabe in Materials: S. S. 302, 304, 316, 316L, 317, 317L, carbon steel, aluminum, alloy, etc.

4. Plastic Random Packing:

(1). Plastic Pall Ring

(2). Plastic Rosette Ring

(3). Plastic Super Intalox Ring

(4). Plastic Cascade Mini Ring

(5). Plastic Saddle Ring

(6). Plastic Heilex Ring

(7). Plastic Conjugate Ring

(8). Polyhedral Hollow Ball

P. S. Plastic Series availabe in Materials: PP, PVC, CPVC, PVDF etc.

5. Metal structured packing

(1). Perforated & corrugated plate

(2). Corrugated plate gauze

(3). Pricked & corrugated plate

(4). Corrugated wire gauze and

(5). Annular corrugated plate

6. Molecular Sieves

(1). Molecular Sieve type 3A

(2). Molecular Sieve type 4A

(3). Molecular Sieve type 5A

(4). Molecular Sieve type 13x

|